Technical Data

Features:

• All our chairs are certified compliant with the requirements of resistance according to EN 12727 Level 4 (severe).

• All our metal structures are guaranteed for 30 years.

• All our backrests are mounted on a central metal structure to allow its row alignment and inclination adjustment ( +/- 5 °).

• All our wood is 100% PEFC / FSC Origin France, 16 mm thick quality A / A (stained, varnished, lacquered) and Grade B / B for fully upholstered parts.

• All our varnish are hydro 0% VOC.

• All our structures are finishing epoxy resin powder .

• All our foams are high quality polyurethane Resilience (HR) with a density of 23-35 kg / m 3 for the backrest and 40-50 kg / m3 for seat.

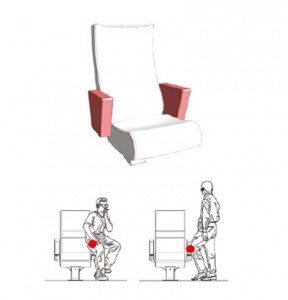

• All systems of the folding writing tablets are activated by the pneumatic cylinder mechanism.

• All our fabrics are conform to the standard AM18, BS5852 Crib5 with “barrier fire” (carbon fiber) complex.

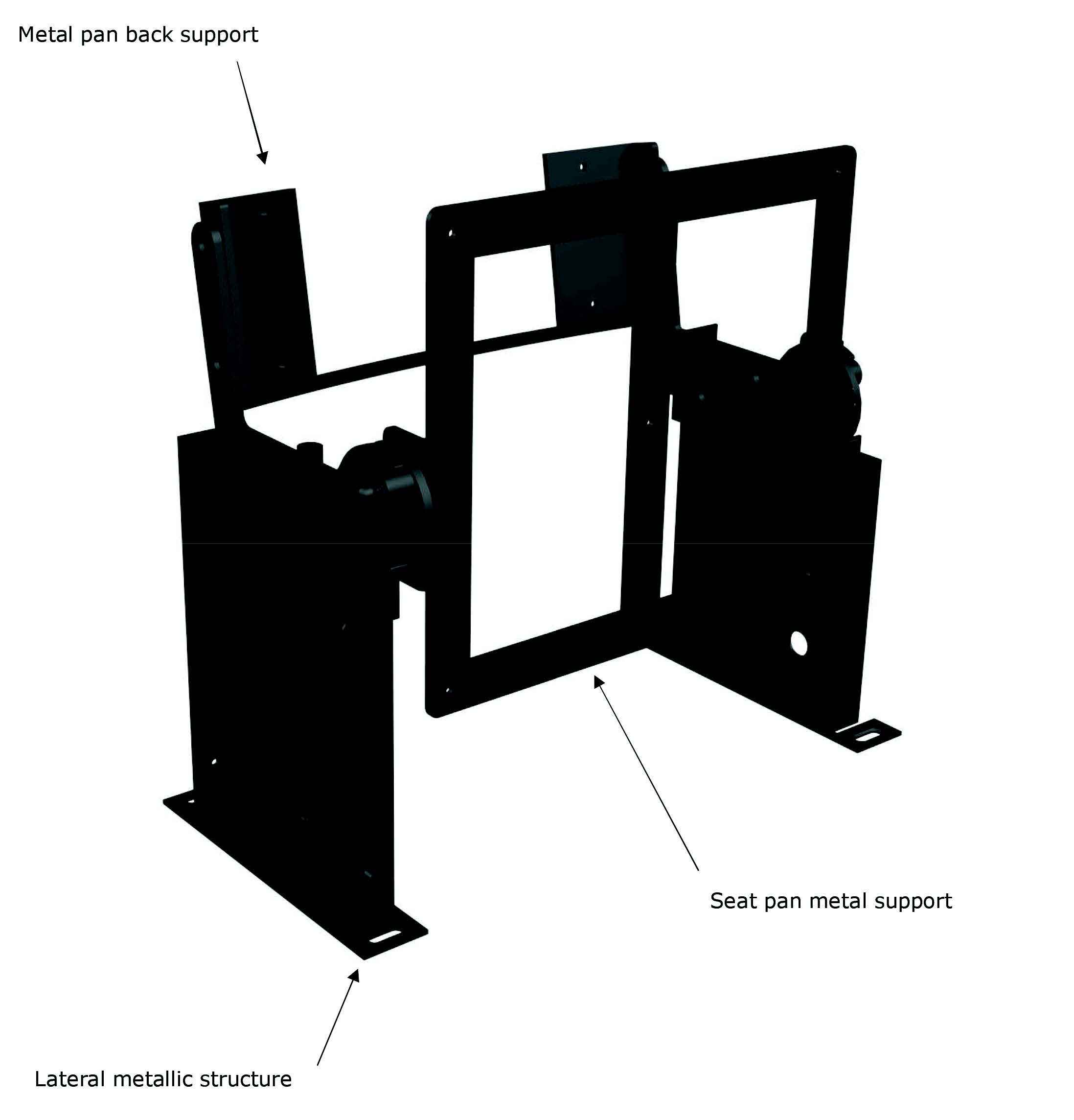

AXE 3 – Central Foot

• Metal stand composed of bearing of sheet metal, thickness 5mm, forming the main seat-support stand and the amrest support stand. The assembly is mechanically welded with floor plate metal filler with four invisible floor fastening points.

• The assembly is anti-corrosion treated, with powder-coated epoxy finish.

BILAX – Lateral Foot

Metal stand composed of bearing of sheet metal, thickness 5mm, forming the main seat-support stand and the amrest support stand. The assembly is mechanically welded with floor plate metal filler with four invisible floor fastening points. The assembly is anti-corrosion treated, with powder-coated epoxy finish.

Patented:

Background

In order to reassure all our customers as to the quality of our products, ConceptD has chosen to become the first armchair manufacturer to certify all the products of its range. This complex, stringent approach enables the consistency of ConceptD’s technical choices to be demonstrated based on the constraints exerted on armchairs in theatre halls.

Developments – Innovation

One of these technical choices consisted of replacing the current systems (lift by inertia, spring or other) with a new method able to meet the standards in force applied to rooms open to the public. The principe of the pneumatic cylinder was developed by our design office, in collaboration with the world-renowned manufacturer (Stabilus).

Product certification

The certification of a product demonstrates compliance with reference guidelines composed of the relevant standards and technical regulations. The attention of certified quality, a quality mark or label is issued by a competent, officially-recognised third party (such as AFNOR or CTBA), separate from the manufacturer, seller or importer. Product certification is voluntary commitment by incumbent carriers of the NF and GS labels. Through this action, they make the quality of their products known to consumers. They must therefore ensure that all conditions are met, both in terms of product quality and the manufactureing process. Declaring one’s product compliant with the standards is easy. But it also needs to be proved ! With certified products, the company holds a veritable passport of permanent evidence of the quality of its products.

Patent pending

Compliance with European Standard PR EN 12.727 level 4, providing for 100,000 seat opening/closing cycles, equivalent to more than 17 years of intensive use, but increased to 200,000 cycles at the request of ConceptD.

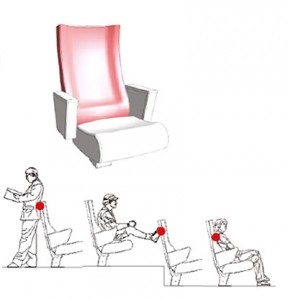

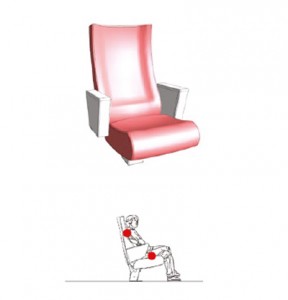

CYLINDER LIFT SYSTEM

• Extremely quiet system incorporating the end-of-travel stops with integrated brake.

• No inadvertent slamming when lifting the seat.

• Seat lifting at constant, controlled speed.

• Seat braking when lifting it at end of travel.

• System reliability, durability and strength integrated, invisibly and inaccessibly, into the structure.

Technical Data:

European Standard EN 12.727 (November 2000) F & GS certified armchairs by the FCBA

BACKREST PERFORMANCE

• 10 consecutive shocks with a mass of 6,5 kg on top of the backrest.

• Force of 90 daN applied 10 times forward horizontally on top of the backrest.

• Force of 33 daN applied 50,000 times horizontally backward on top of the backrest.

SEAT PERFORMANCE

• 10 free falls with a mass of 25 kg at the center of the seat.

• Force of 95 daN applied 150,000 times on the front edge of the seat.

• 200,000 complete seat opening/closing operations.

ARMREST PERFORMANCE

• Force of 100 daN applied vertically downwards onto the end of the armrest.

• Force of 100 daN applied laterally onto the end of the armrest.

• 10 consecutive impacts of mass 6,5 kg on the end of the armrest.

ARMCHAIR PERFORMANCE

• Combined force of 200 daN on the seat and 76 daN on the bacrest applied ten times simultaneously.

• Combined force of 95 daN on the seat and 33 daN on the backrest applied 150,000 times simultaneously.

FOAM PERFORMANCE

• Force of 75 daN applied 80,000 times on the foam.

• Mass of 45 kg applied for 72 hours.

Environment:

Our commitments

CIPE-classified production site

Being a Classified Installation for the Protection of the Environment means :

• Recognition of regulatory compliance.

• Self-supervision and self-monitoring of the production site.

• Preventive maintenance of facilities.

• Waste management :

– No waste released into the aquatic environment.

– No waste released into the ground.

• Compliance with the French ministerial decree of 2 February 1998 on sampling and water consumption and on emissions of any kind from Classified Installations for the Protection of the Environment. This particularly restrictive obligation on French manufacturers compels us to excel.

NF Environment mark (product certificate)

• Range of products certified NF Environment since 2006.

• Objective: 100% of products certified.

• Main requirements :

Environmental safeguards :

– Discharge into water and air minimised, monitored and recorded; waste recovery.

– Absence of heavy metals and CFCs.

– Demountable and recoverable at end of life.

Economic safeguards :

– Suitability for use and sustainability of products.

Employee safeguards :

– Reduction in the chemical risk faced by employees.

– Certifying Body: FCBA.

ISO 14001 (Production system certification)

• ConceptD Delagrave has undertaken to demonstrate, via standard ISO14001, its capability in producing and supplying products complying with the environmental requirements.

• Our Environmental Management system is based on standard FD X 30—205, which provides a framework for the company in order to achieve its objective of certification for the different levels (three in total).

• Level-1 certification obtained in 2007, under consideration for level 2.

PEFC (resource certification)

• PEFC (Program for the Endorsement of Forest Certification) certified since 2006.

• Environmental safeguard: sustainable management of forests and of the consumption of wood and wood products.

• Preservation of local resources: production site in Franche-Comté, the most densely-wooded region of France.

• Employee safeguards: observance of the labourcode and other regulations in force.

• Certifying Body: FCBA.

• 100% of our products are PEFC-certified.

Grenelle environment forum (Valdelia)

• Subsequent to the works of the Grenelle environment forum, commercial furniture marketers are henceforth reponsible for managing any waste from furniture components.

• In order to meet their obligations, 13 industrials firms, including DELAGRAVE Group, all memebers of the UNIFA, created VALDELIA (VALorisation des DÉchets Liés à l’Ameublement : recovery of furnishing-related waste) a future Eco-body approved by the French ministry for ecology, sustainable development and energy.

• With the introduction of this recycling chain, holders of furniture will benefit from a veritable service meeting ambitious collection and recycling objectives.

• Valdelia provides a service for the collection and treatment of waste furniture elements (DEA : déchets d’éléments d’ameublement) for holders complying with certain conditions.